Loop Slitting Lines

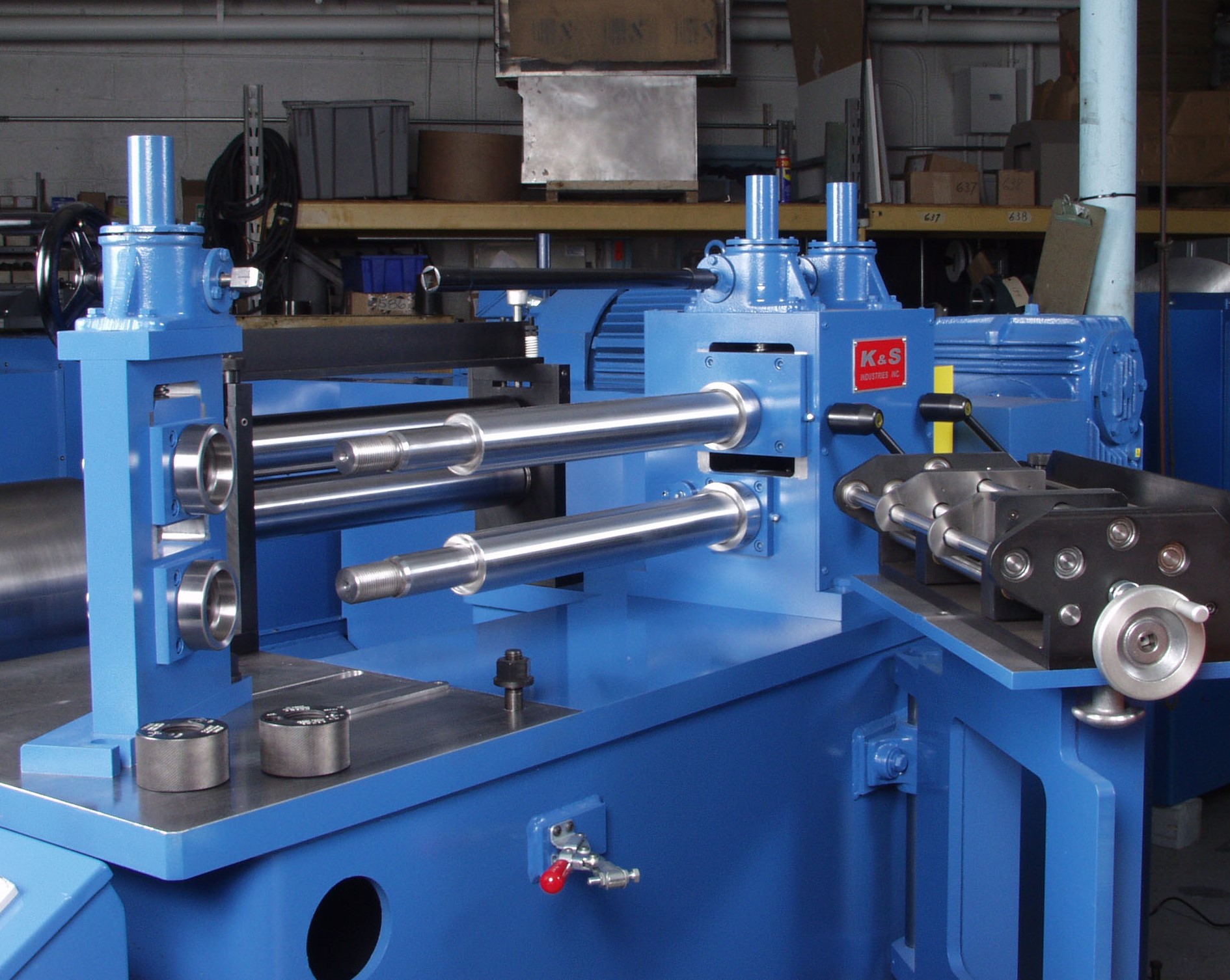

Double Loop Slitting Lines

- .001” to .125” thickness

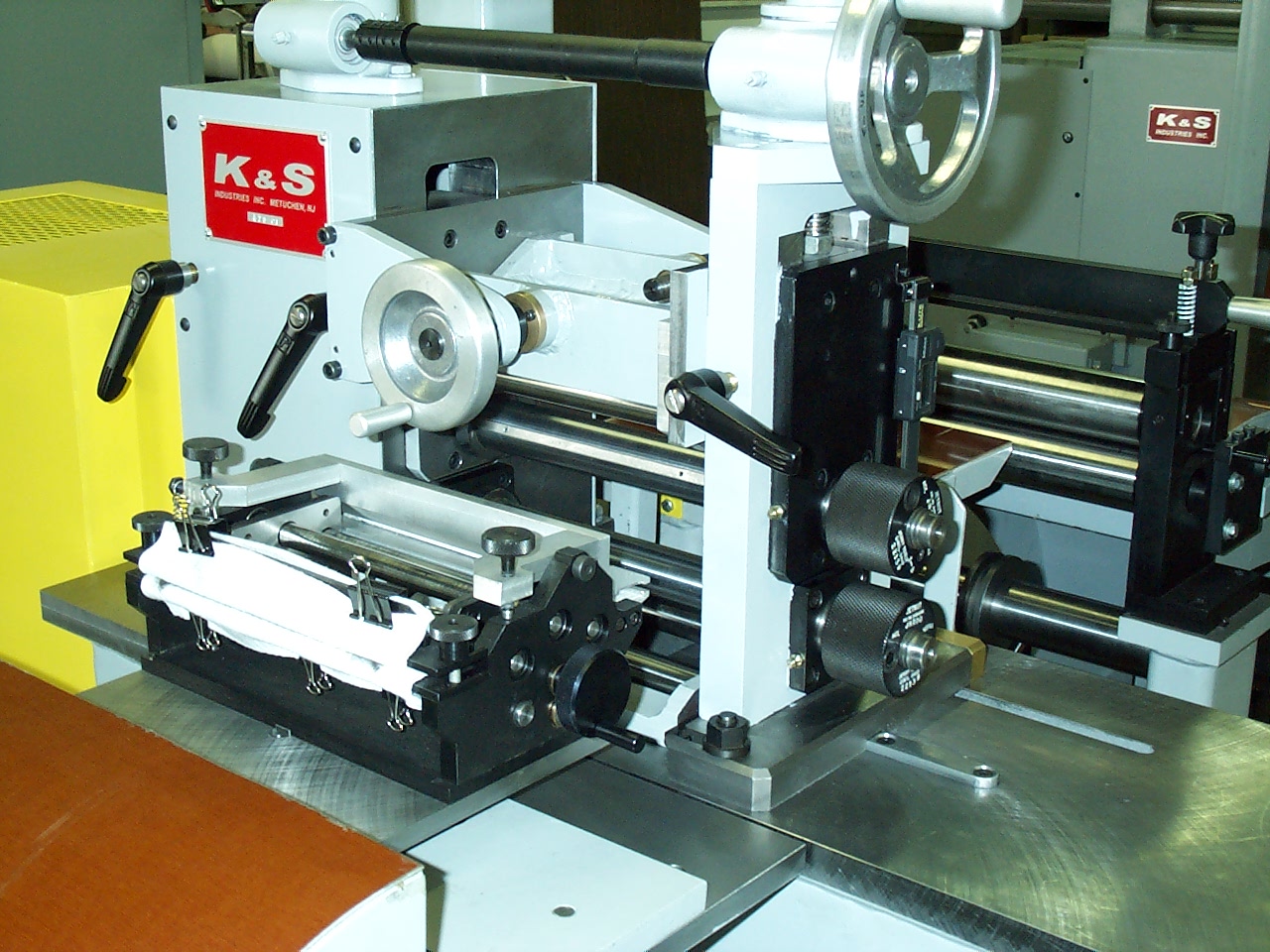

Light Gauge Slitter Stand

Precision Elevating Tension Stand

Precision Slitter Head

Injector Head Slitter

Double Loop Slitting Line

Multi-axis, fully automatic AC vector-driven

Main operator control station with 19”/480 mm color, touch screen providing

- bird’s-eye view of the machine

- Intuitive set-up and diagnostic screens

- Alarms, messages, and instructions

Tension-controlled uncoiler

Ultrasonic sensor for in-process coil diameter calculation

Uncoiler operation station with 6”/150 mm color, touch screen

- Uncoiler, paper winder, pull bridle set-up

Automatic edge guide

Pull bridle with driven cascade rollers

8”/200 mm Slitter knife diameter and operator station

Dual servo knife positioners and linear feedback sensors

Dual slitter head changeover station

Prepare next step while processing current

Smooth linear rail-guided movement

Semi-automatic position of next slitter head

Head easily slides into then locks in place

Driven cascade rollers at exit loop

Ultrasonic sensors for loop position feedback

Elevating tension stand

Hydraulic-driven screw for continuous positioning

Recoiler operator station with 6”/150 mm color, touch screen

- Recoiler, paper unwinder, tension stand set-up

Optimal rewinding approach maintained by coil diameter sensor

Precise coil wrap

State-of-the-art PLC, brushless servo and vector controls

Profi-Net and Profibus networks

Servo and vector drives on energy-saving common DC bus

200 kw common DC bus rectifier

Remote I/O station on Profi-Net network

30 kw recoiler

Two, 13 kw tension stand motors

34 kw slitter with quick-change heads

Four servo-driven cascade rollers

8 kw pull bridle

13 kw uncoiler

Precision Slitter Head

New Quadruplex precision bearing design.

Shoulder runout within .000080”

Anti-backlash jack boxes for precise vertical adjustment

8½” – 36½” wide

Driven uncoiler

Entry and exit loop sensors

Entry table

Precision slitter head

Driven exit pinch rolls

Wiper or driven pinch roll tension stand

Integral scrap winder, bailer, or chopper

Recoiler drums/arbors from 2” – 30” diameter (or larger, upon request)

Integral over-arm separator

State-of-the-arm drives and controls

Ultra precision shimless tooling